Contents

Preface

EN 50155 is a standard established in Europe for electronic equipment used in railways. Most countries choose to take reference to this regulation, which encompasses various testing standards such as input voltage, I/O isolation voltage, insulation voltage, electromagnetic compatibility (EMC), mechanics, and rigorous reliability testing for harsh environments, taking into account testing factors like operating temperature, cooling, humidity, vibration, and shock.

Having successfully obtained the EN 50155 certification, MINMAX's railway-certified DC-DC converters support a power range from 3 watts to 150 watts and come in various international packaging options such as DIP, 2" x 1", and quarter bricks. These converters also feature wide input voltage range, extended operating temperature range, reinforced insulation, deviation management, remote on/off control, output voltage trimming capability, output voltage monitoring, and more. Furthermore, they have met fire protection testing standard (EN45545-2), railway electromagnetic compatibility (EMC) standard (EN50121-3-2), vibration and shock reliability testing standard (EN61373), environmental testing standard (IEC 60068-2-1-2-30), international safety regulations (IEC 62368-1 certification), and carry the CE mark.

With optimized PCB layout design and thermal management, MINMAX's products maintain a high level of stability in overall efficiency, power loss, and heat generation, regardless of drastic fluctuations in input voltage, output current, and environmental temperature. Furthermore, our products can even meet 100% of the current and power requirements of the backend load system right at the moment of startup, rapidly supplying the rated output voltage and satisfying the optimized system load driving capability.

MINMAX not only provides suitable products but also offers comprehensive services to earn the trust and support of end users. These services include providing analysis and verification required by customers during the development process when using MINMAX products, as well as offering special designs tailored to customer needs. We are dedicated to serving you and ensuring that your customers closely cooperate with you.Wide Input Voltage Range

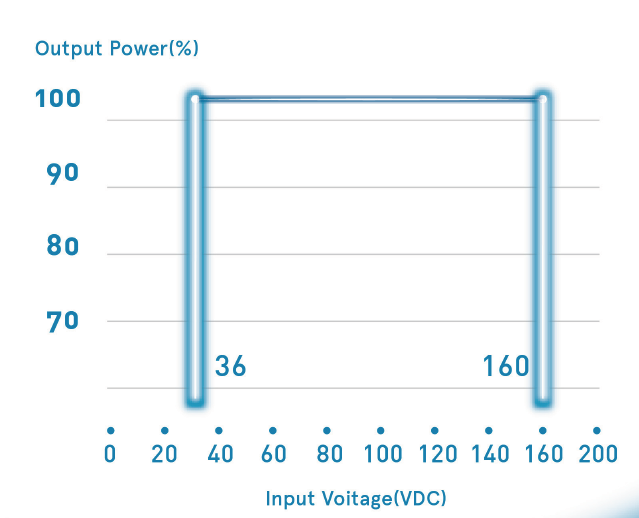

The voltage distribution in railway DC systems ranges from 24V, 28V, 36V, 48V, 72V, 96V, to 110V. To accommodate transient conditions, the voltage range must cover 0.6 to 1.4 times the rated center voltage.

MINMAX's railway-certified DC-DC converters mostly support a wide input voltage range of 4:1, with the actual ranges covering 9-36, 18-75, and 40-160VDC, allowing them to meet the voltage requirements of all railway equipment. Additionally, MINMAX has developed an input voltage specification of 36-160VDC specifically for applications that require low-voltage startup.

Figure 1 - Ability to Provide 100% Output Power within the Rated Input Range

High-Precision Output Voltage

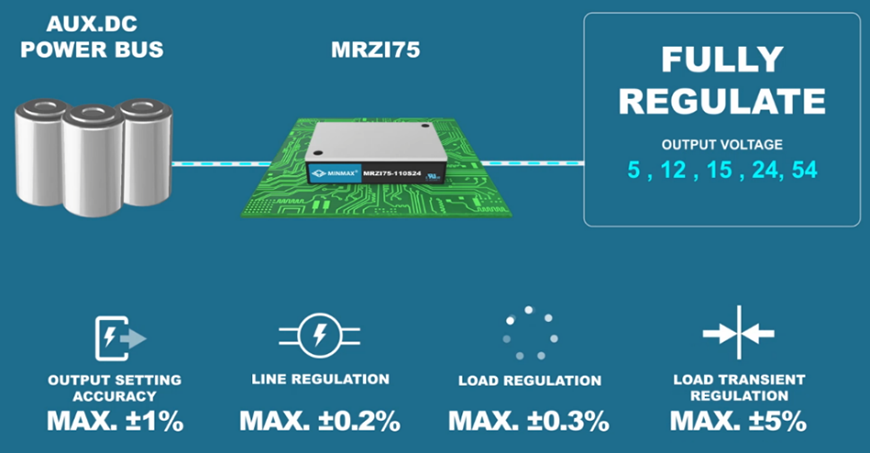

Typically, railway batteries do not have voltage stabilization devices. Therefore, MINMAX's railway-certified DC-DC power modules must withstand the following three conditions of railway batteries during operation:

- Voltage fluctuations ranging from 0.7 Vn to 1.25 Vn

- Voltage drops of 0.6 Vn within 0.1 seconds

- Surge voltage of 1.4 Vn for one second during battery startup

To prevent any negative impact on railway operation systems caused by uncertainties in input voltage, output load current, and surrounding temperature, MINMAX's railway-certified products adopt a special design that ensures ultra-high precision output voltage. In addition, MINMAX's railway-certified products offer an output voltage of 54V, making them particularly suitable for PoE (Power over Ethernet) applications. This feature effectively compensates for voltage losses that occur during long-distance power transmission.

Figure 2 - Stable and Precise Output Voltage Accuracy is Essential

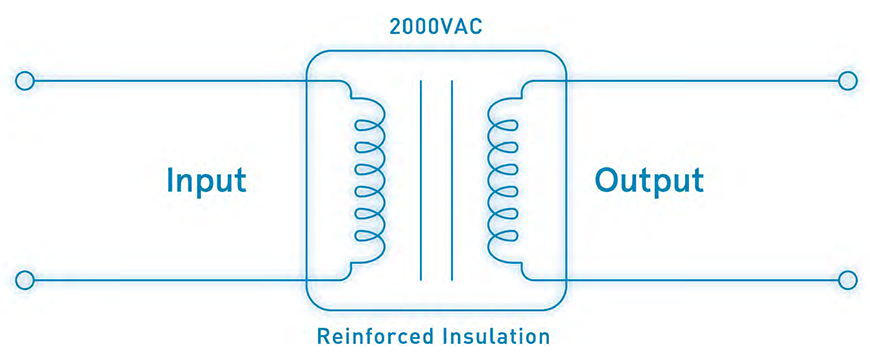

High Isolation Voltage with Reinforced Insulation System

MINMAX's railway-certified products feature reinforced insulation, an isolation voltage of 2KVAC, and a fully encapsulated design to create a robust insulation barrier that withstands high voltage levels. This ensures the protection of sensitive system circuits from noise, electromagnetic interference, power bus fluctuations, electrical shocks, surges, transient voltage spikes, insulation breakdown, mechanical damage, fire hazards, and the risks of gaps, arcs, and short circuits in PCB circuit boards. These features provide optimal safety assurance for railway equipment operating over the long run.

Figure 3 - MINMAX's Railway-Certified Products Pass the 2KVAC Isolation Voltage Test with Reinforced Insulation

Excellent Thermal Design

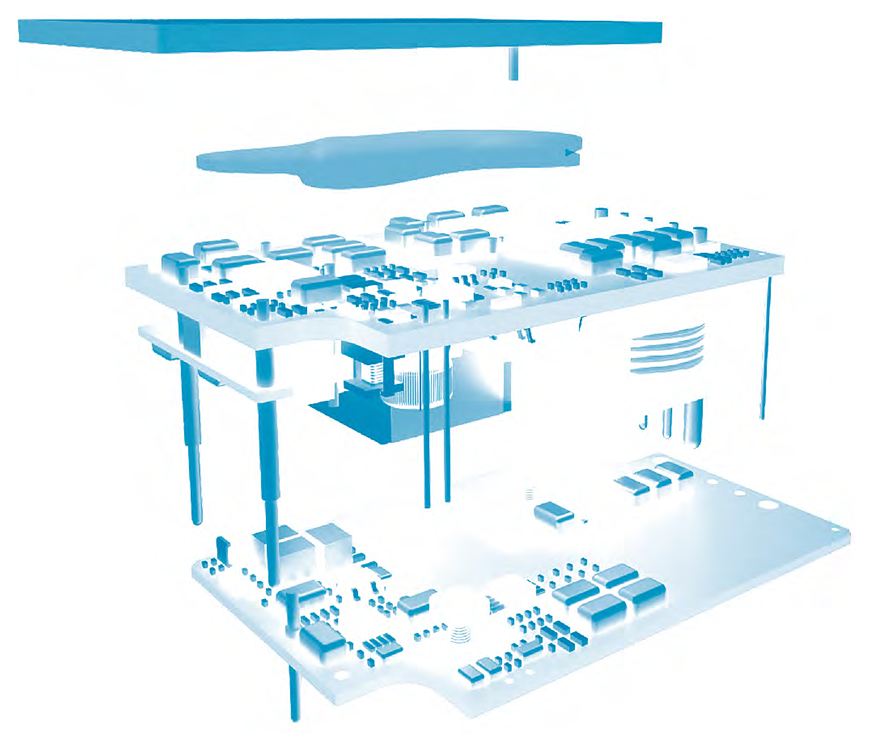

Through optimized thermal structure design, such as high thermal conductivity adhesives, low thermal resistance components, and optimized PCB layout, we ensure improved thermal performance and long-term heat dissipation capability. This design provides the best safety and reliability assurance for railway equipment operating in harsh environments over extended periods.

Figure 4 - Adoption of Optimized Thermal Design

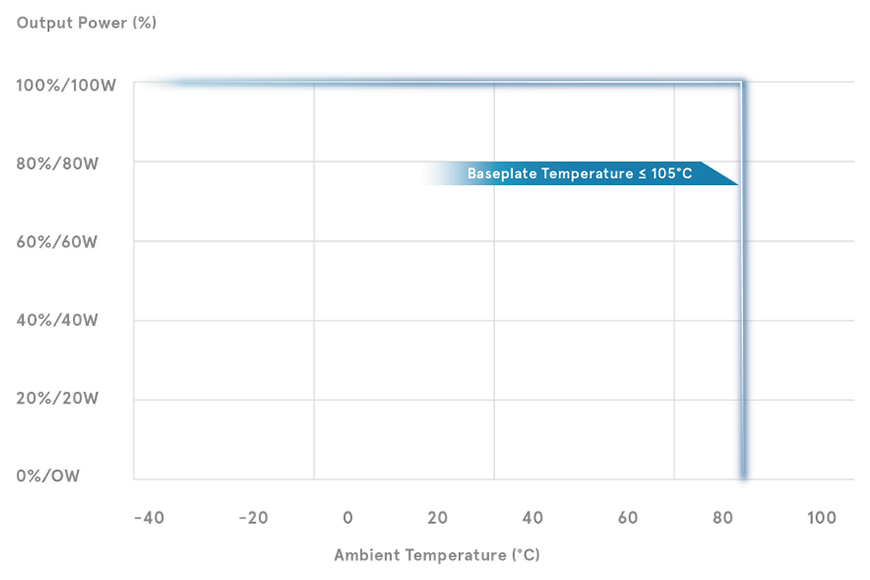

Wide Operating Temperature Range

In many railway applications, temperatures can reach extremely high levels at +60°C or even higher in summer and plummet to extremely low levels at -30°C or even lower in winter.

Therefore, expanding the operating temperature range of products is an important challenge. MINMAX's railway-certified products have passed optimized overall electrical and thermal design, supporting a temperature range of -40°C to +85°C to meet the stringent requirements of railway applications in various environmental conditions.

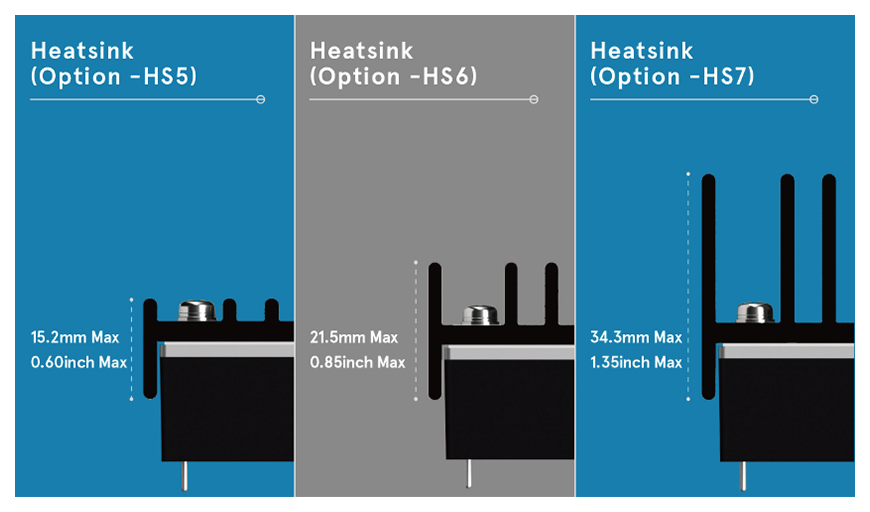

Effective Thermal Dissipation Mechanism

The majority of MINMAX's railway-certified products offer a selection of three different heights of heat sinks to cater to various operating temperature requirements.

Figure 5 - Flexible Selection of Heat Sink Options

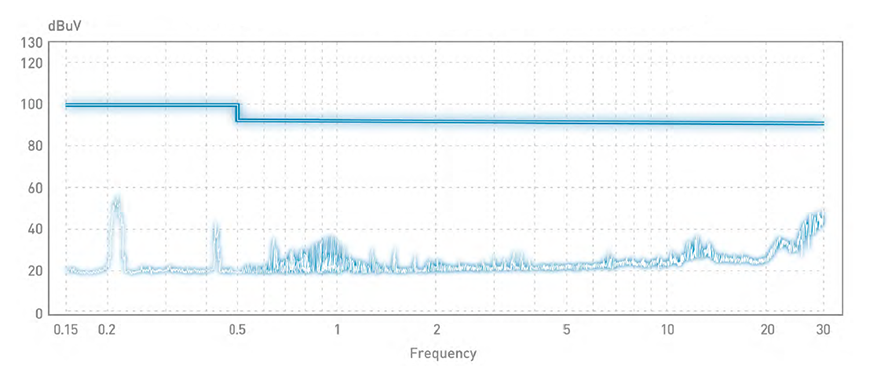

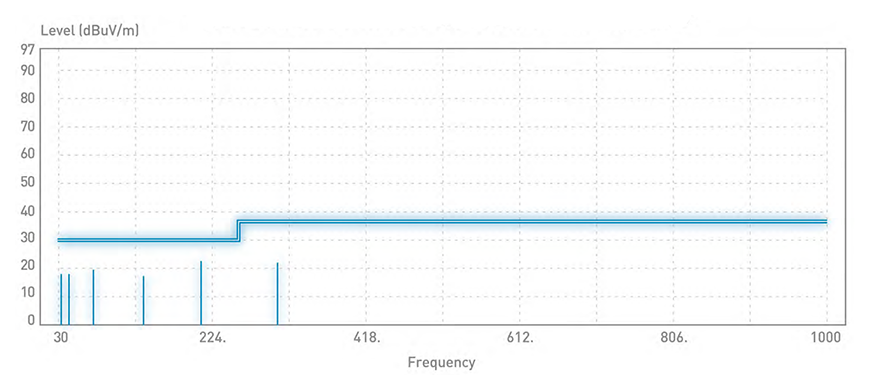

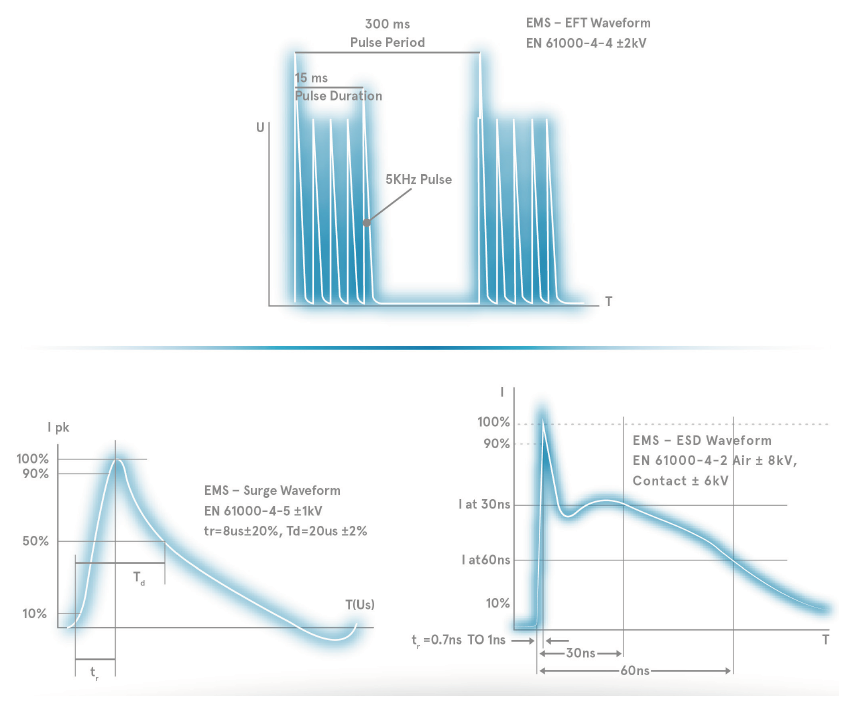

Excellent EMC Performance

MINMAX's railway-certified products exhibit excellent EMC performance through enhanced noise filtering technology. This helps reduce electromagnetic interference from power modules in the system, thereby improving the system's conductive and radiative EMI performance, as well as its electrostatic discharge (ESD), surge, electrical fast transients (EFT), conducted susceptibility (CS), radiated susceptibility (RS), and power frequency magnetic field tolerance (PFMF) in terms of EMS performance.

Figure 6 - Conducted EMI compliant with EN 50121-3-2 standard

Figure 7 - Radiated EMI compliant with EN 50121-3-2 standard

Figure 8 - Compliance with various EMS testing standards of EN 55024

End of Isolated DC-DC Power Converters for Railway Certification: An In-depth Analysis of Uncompromising Performance (Part 1)

Thank you for watching. If you are interested, please refer to the next episode : Isolated DC-DC Power Converters for Railway Certification: An In-depth Analysis of Uncompromising Performance (Part 2)

For more information,please click on the following links:

- 【MINMAX Railway Certified Products _ Power Solutions】

- 【MINMAX Railway Certified Products _ Product Selection Guidebook】

- 【MINMAX Railway Certified Product _Product Introduction Video】

- 【MINMAX Railway Certified Series _ Quarter Brick_MRZI150 Series】

- 【MINMAX Railway Certified Series _ 2" x 1"_MKZI40 Series】

- 【MINMAX Railway Certified Series _ DIP-24_MIZI03 Series】